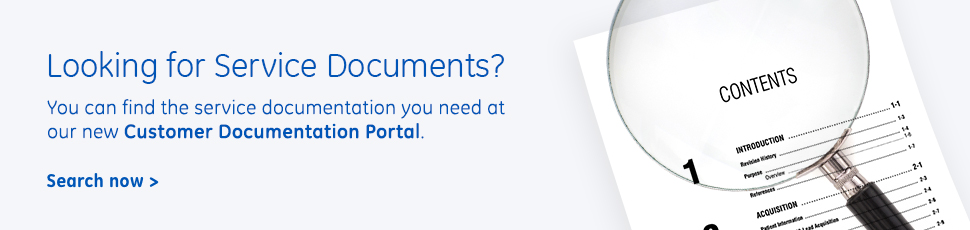

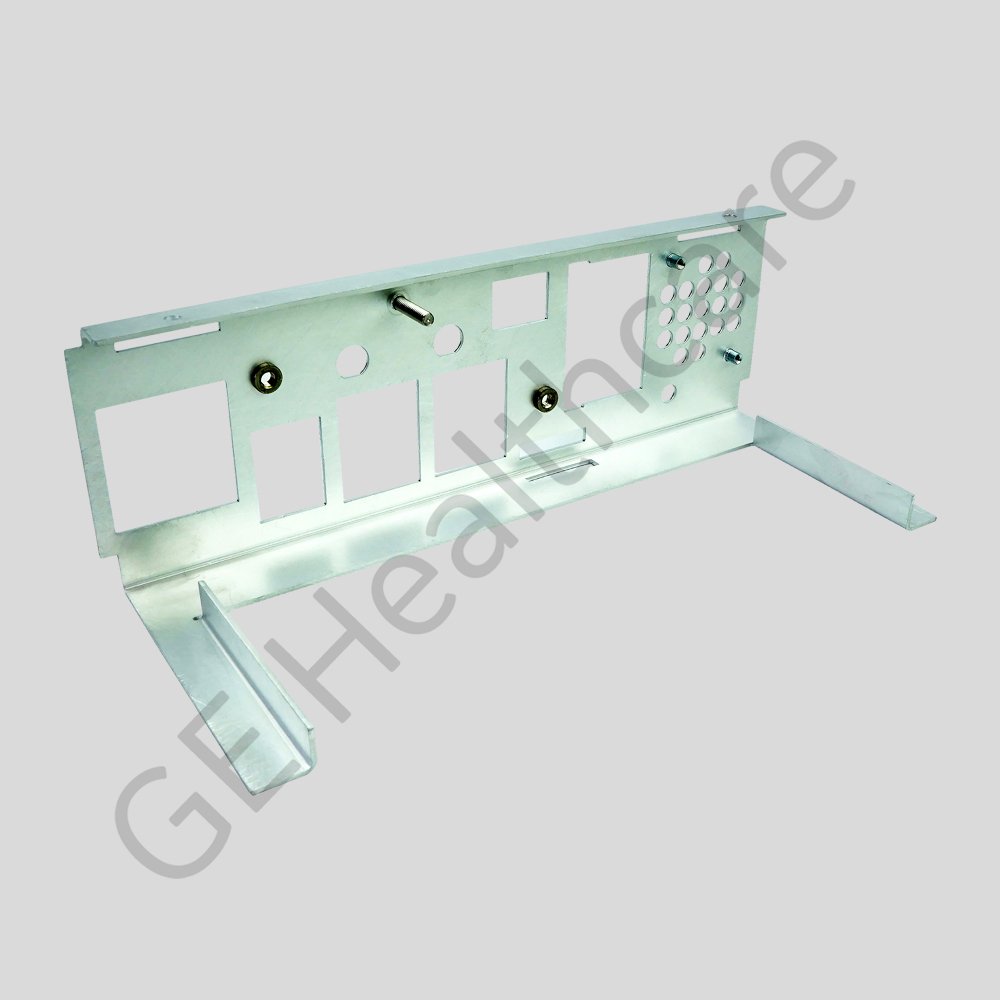

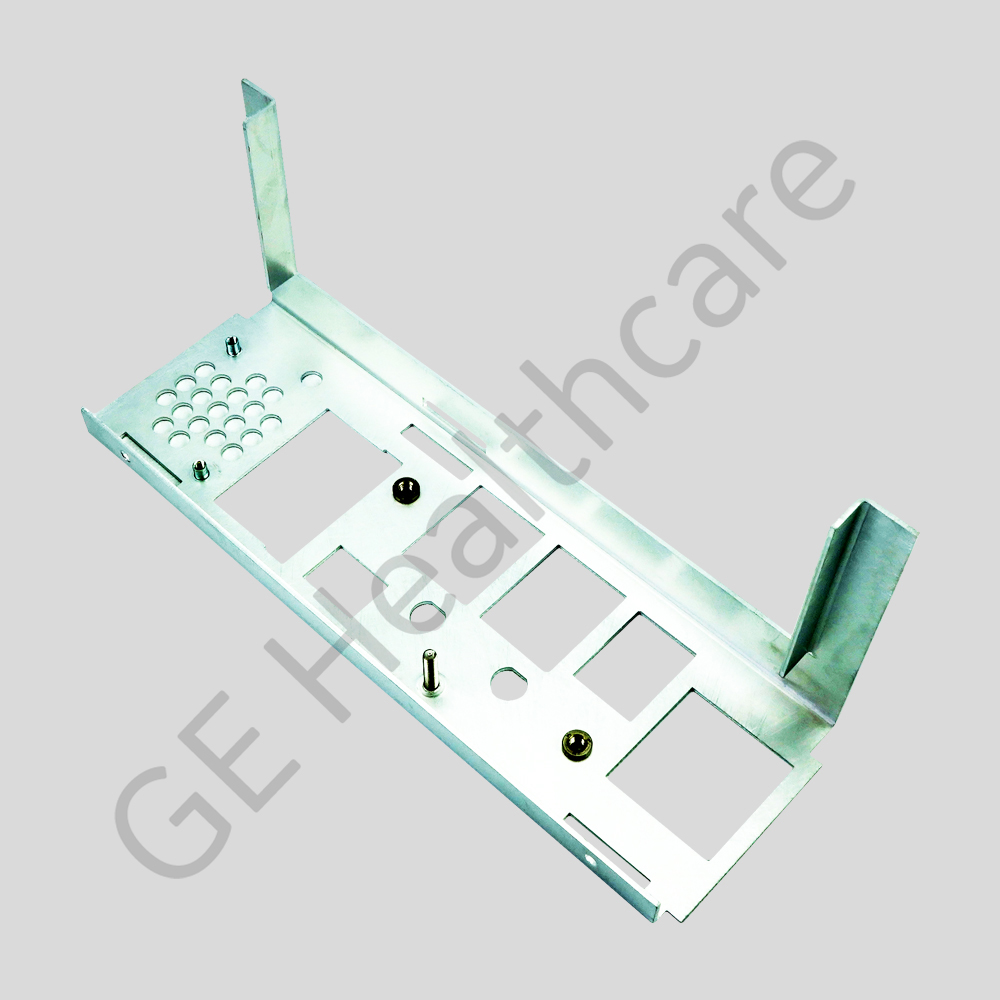

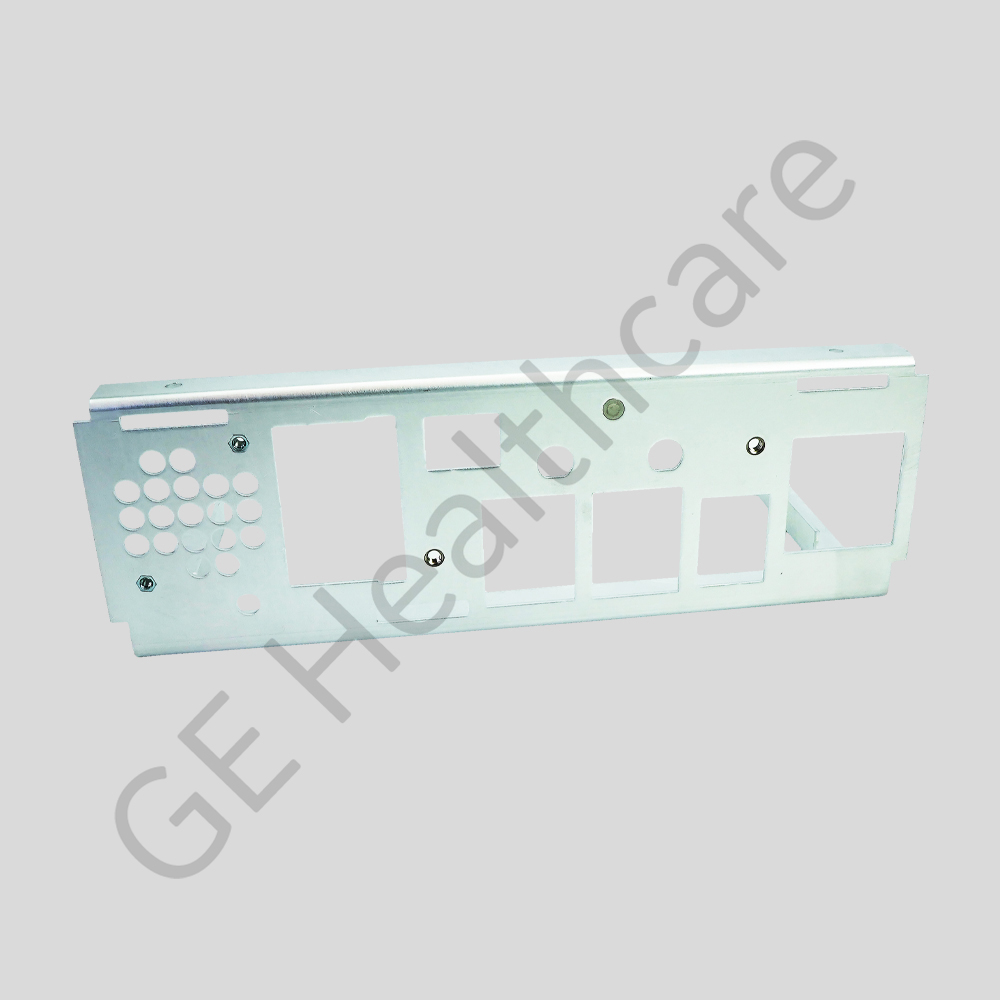

Rear Electronic Plate Machined - Outlet Panel

| 6600-2154-500 | |

| Maternal Infant Care | |

| GE Sistemas Médicos de México S.A. de C.V | |

| GE HealthCare | |

Enter your approval number and submit to add item(s) to cart.

Please enter approval number

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without the

approval number, GE will contact you before your order

can be confirmed for shipment.

Select your approver's name and submit to add item(s) to your cart

Please Select Approver Name

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without

selecting an approver, GE will contact you before your order

can be confirmed for shipment.

Features

- Very good corrosion resistance

- High fatigue strength

- Weldability and moderate strength

- Good workability

Product Overview

The Rear Electronic Plate is used in the outlet panel electronic enclosure assembly, which is part of the Maternal-Infant Care system. It is a panel plate used to assemble circuit breakers, mains switch, power inlet/outlet, cord retainer, alarm speaker, RS-232 connector, RS-232 ISO plate, and ground screws. It is fixed at the bottom of the heater housing electronic enclosure assembly, in between enclosure rear panels and power board by the use of screws. The rear electronic plate is made up of Aluminum 5052-H32. It contains nominally 2.5% magnesium and 0.25% chromium. It has good workability, medium static strength, high fatigue strength, good weldability, and very good corrosion resistance, especially in marine atmospheres. It also has excellent thermal conductivity and the lowest density common to all aluminum alloys. It is commonly used in sheet, plate and tube form. The plate finished with advanced plating technologies provides clear, trivalent aluminum chromate conversion coatings to MIL-DTL-5541, commonly as an undercoat prior to powder coating application. Aluminum chromate conversion coatings improve the corrosion resistance of wrought, heat treatable and cast aluminum alloys while providing an excellent base for subsequent painting or powder coating services.

Additional Features

- Good cold formability

- Excellent thermal conductivity

- Low maintenance

- Anti-Static

- Light-weight

- Low density

- RoHS compliant